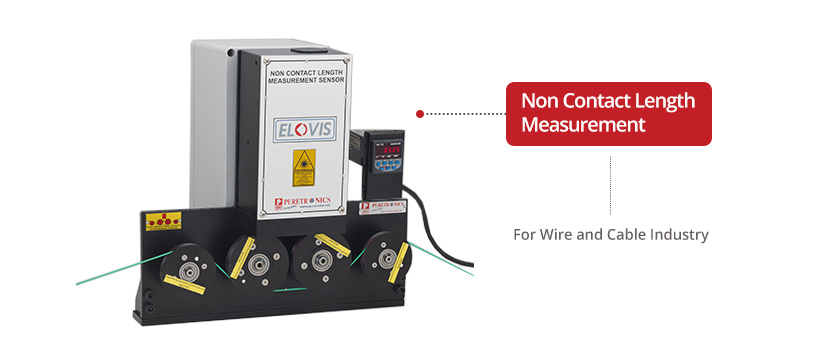

Non-Contact Length Measurement Sensor is proudly introduced by Puretronics in collaboration with a German Company.

µSPEED systems are capable of measuring speed and length without contact to the moving material surface. The systems replace tactile measurement solutions as e.g. contact wheels, which tend to measurement errors caused by slippage, chatter, dirt build-up and day to day wear problems. The maintenance free and long term calibrated µSPEED systems measure nearly all surfaces without parameter setting.

Ready solution for measurement of :

- Length

- Part Length

- Standstill

- Area Measurement

- Speed

- Movement

- Direction of Movement

- Slippage

- Elongation

- Repeat Length

- Shrinkage

- Mark Distance